Custom Pyramid Cake Boxes

Why Pyramid Boxes Packaging is Popular in Modern Branding

Explore Our Custom Pyramid Boxes Packaging Solutions

Materials & Finishes for Pyramid Packaging

Kraft Paper / Coated Paper / Rigid Cardboard

Our pyramid packaging uses top-tier materials with eco-focus:

Kraft Paper: 100% recyclable, biodegradable, rustic charm—ideal for sustainable brands, budget-friendly.

Coated Paper: FSC-certified options, smooth surface for vivid custom prints, recyclable.

Rigid Cardboard: Sturdy, luxe feel, made with recycled fibers, ensuring durability and eco-responsibility.

Shenzhen Sunshine Bakery Packaging Co., Ltd. adds finishes like water-based coatings, boosting sustainability and brand appeal.

Matte Lamination, Foil Stamping, Spot UV

Elevate pyramid boxes with eco-conscious finishes:

- Matte Lamination: Water-based, recyclable, softens texture—ideal for organic brands.

- Foil Stamping: Uses minimal metallic, pairs with FSC paper for luxury minus excess waste.

- Spot UV: Precision application reduces chemical use, enhancing details on recycled substrates.

Shenzhen Sunshine Bakery Packaging Co., Ltd. blends these with sustainable materials, boosting SEO and converting eco-aware buyers.

Sustainable & Recyclable Materials

Our pyramid boxes prioritize sustainable, recyclable materials: FSC-certified kraft paper (100% recyclable), biodegradable coated stock, and rigid cardboard with recycled fibers. All meet EU/US eco-standards, aligning with green branding. Shenzhen Sunshine Bakery Packaging Co., Ltd. ensures these materials retain durability and printability, boosting SEO for eco-conscious searches while driving conversions with responsible choices.

OEM & Customization Services

Custom Dimensions and Folding Structure

Pyramid boxes offer exceptional flexibility in custom dimensions—from compact sizes for jewelry or chocolates (e.g., 3x3x3 inches) to larger formats for gift sets or event favors (up to 12x12x12 inches)—tailored precisely to fit your product. Their folding structures are engineered for ease: pre-scored creases enable quick, tool-free assembly, while flat-packed shipping reduces storage/transport costs. Designs often include自锁 or tuck-flap closures for secure sealing, balancing functionality with the iconic pyramidal shape.

Logo Printing (CMYK, Pantone, Hot Stamp)

Pyramid boxes support versatile logo printing to match your brand’s needs:

- CMYK: Ideal for full-color, intricate logos with gradients or photos, delivering vibrant, multi-hued results on paper-based materials.

- Pantone: Ensures precise color consistency for brand-specific shades (e.g., a signature logo hue), perfect for maintaining brand identity across batches.

- Hot Stamp: Adds luxury with metallic or matte foils (gold, silver, or custom tones), creating a raised, tactile finish that elevates logos—ideal for premium or gift-focused branding.

Special Closures (Ribbons, Magnets, Handles)

Special closures elevate pyramid boxes’ functionality and appeal:

- Ribbons: Add a touch of elegance—satin or grosgrain ties secure the box while doubling as a decorative accent, perfect for gifts or events.

- Handles: Boost practicality—paper or fabric handles make the box easy to carry, great for retail products or on-the-go gifts, blending convenience with style.

MOQ and Production Timeline

We support OEM and customization with clear MOQ & timelines: MOQ 500 units for standard pyramids, 1,000 for complex structures. Post-sample approval, production takes 20-25 days (500-5,000 units) or 25-30 days for larger batches. Share your specs—we’ll confirm feasibility and adjust timelines within 24hrs.

Why Choose Us as Your Pyramid Box Manufacturer in China

Choose us as your China pyramid box manufacturer: 100% in-house manufacturing ensures quality control. Fast sampling and flexible MOQ fit diverse needs. With 10+ years exporting to 50+ countries, we know global demands. FSC-certified materials available—trusted, efficient, and compliant.

Certificate display

FSC

BSCI

SGS

SunShine

WHAT CLIENTS SAY?

I love them.They are beautiful,great quality and easy to put together.

— KELLY MURRY

ACME Inc.

“Thank u Fiona.Say thank u.To everybody.There who worked making.My cake drums.“

— JEREMY LARSON

ACME Inc.

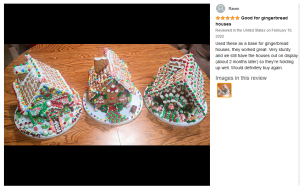

Raven

Raven

★★★★Good for gingerbreadhouses

Reviewed in the United States on February 10,2022

Used these as a base for gingerbreadhouses, they worked great. very sturdyand we still have the houses out on display(about 2 months later) so they’re holdingup well. Would definitely buy again.

lmages in this review

Amazon Customer

★★★★★Very good quality

Reviewed in the United States on November 6,2021

very good quality. will def be purchasingagain.

lmages in this review

I received my order and l love them

I am very happy with the purchase

Technical Insights & Buying Guide for Pyramid Boxes Packaging

How to Choose the Right Pyramid Packaging for Your ProductUnderstanding Pyramid Boxes Packaging from a Manufacturer’s Perspective

Structural Design Principles of Pyramid Boxes

Pyramid boxes feature 3 key structures:

4-panel fold: Collapsible, easy to assemble/ship—ideal for bulk retail like gift boxes.

Lock-bottom: Sturdy, quick to set up—suits food packaging (e.g., pyramid cake boxes).

Glued-edge: Permanent structure, premium feel—perfect for luxury favors or wedding gifts.

All balance portability and functionality, fitting diverse use cases efficiently.

How Shape Affects Material Consumption & Unit Cost

The pyramid shape impacts material consumption and unit cost through its structural uniqueness:

- Material consumption: Unlike rectangular boxes with straight, parallel sides, pyramids have sloped, converging faces. Their unfolded structure is more irregular, often leaving more leftover material during cutting—boosting material usage compared to simpler shapes. For example, a pyramid of equal volume to a square box may require 10-15% more paperboard due to inefficient nesting of its angled panels.

- Unit cost: Higher material use, plus the need for precise die-cutting and folding (to maintain the pyramid’s symmetry), increases production complexity. This raises manufacturing costs compared to standard boxes. However, the shape’s premium appeal often justifies the extra expense for brands prioritizing differentiation.

Material Selection Guide for Pyramid Boxes Packaging

Which Material is Best for Your Use Case?

Comparing materials for pyramid boxes:

Grey board + paper: Moderate cost, good structure; eco-friendly if paper is recycled.

White card: Sleek look, smooth feel, higher cost, less eco than kraft.

Kraft paper: Low cost, eco-friendly, rustic texture, natural appearance.

Environmental Impact and Certifications

Pyramid boxes offer strong environmental benefits—reducing material waste, being recyclable—and often carry certifications like FSC, aligning with sustainable standards.

Best Practices for Customizing Pyramid Boxes

The file format and die-cutting standards suggested by the factory

For optimal production, we recommend AI/PDF vector artworks for precise printing and die-cutting. Our factory’s die-cutting solutions align with industry standards, ensuring seamless integration with your designs. Shenzhen Sunshine Bakery Packaging Co., Ltd. offers tailored die mold coordination, guaranteeing accurate shapes—from pyramid boxes to custom sizes—for efficient, high-quality manufacturing.

MOQ minimum order quantity suggestions & Sample cycle control

Our MOQ recommendations vary by box type: 500 units for standard pyramid boxes, 1,000 for complex die-cut or custom-shaped ones like multi-layered platter boxes. Sample lead time: 3-5 days for basic designs, 5-7 days for intricate structures with special finishes.

Market Trends & Innovative Use Cases

Pyramid Boxes in Wedding, Beauty, and Gift Packaging

In the world of baking packaging, pyramid boxes have opened up a new market, especially in weddings, restaurants and cake shops. Their unique shapes not only enhance the aesthetic appeal but also bring a touch of novelty to the product display.